Improve customer experience and protect your business case with the precise collection of real-time data

From managing food in franchise businesses to tracking operating supplies or raw materials in the industry: real-time information about current consumption, correct fill levels, and the authenticity of materials are of great importance for smooth operations. Especially when these consumables are replaced directly by your customer, this can be a challenging task where integrating RFID into your machine can help.

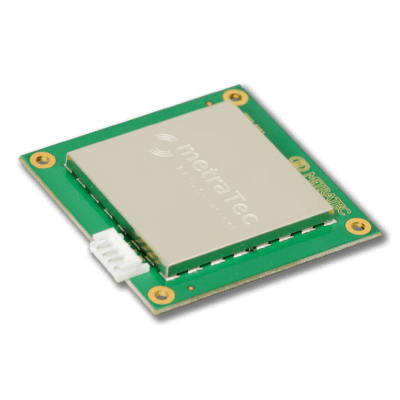

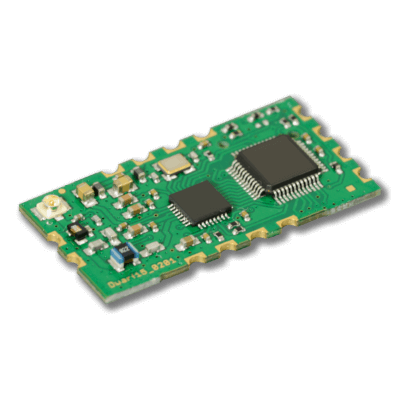

For this purpose, RFID tags are attached to consumables, and suitable embedded RFID modules are installed in machines and other equipment to uniquely identify the consumables and read or write data to the transponders. This turns your consumables into mobile data carriers. Your machine not only knows whether a replacement part is genuine but also gives you the data to determine when fill levels fall below a specified minimum and how your product moves through the supply chain. In addition, information on shelf life can be recorded, thus increasing product safety, preventing waste, and protecting consumer health.