RFID in Measurement Equipment

A sensor with wrong calibration data delivers wrong measurements. A measuring device that doesn’t know when it was last calibrated jeopardizes quality assurance. That’s why measurement equipment manufacturers integrate RFID into their products.

The Problem

Measuring instruments work with sensors, test equipment, and consumables. A pH meter needs the right electrode with current calibration values. A breathalyzer needs certified mouthpieces. A water meter must be uniquely identifiable.

Currently, calibration data is documented on paper or maintained in databases. It works – as long as someone maintains the data and the assignments are correct. But papers get lost, databases aren’t updated, and the sensor from the neighboring device looks exactly the same.

The Solution

An RFID tag on the sensor stores its calibration data directly. The measuring device reads the tag, instantly knows the calibration curve, the date of last calibration, the serial number. No mix-ups, no outdated data.

After recalibration, the device writes the new data to the tag. The sensor carries its complete history with it – regardless of which device it’s connected to.

This works for consumables too: A breathalyzer recognizes the disposable mouthpiece and knows it’s unused. After the test, the tag is marked – reuse excluded.

Why Manufacturers Want This

Measurement accuracy is the main reason. Wrong calibration data means wrong measurements. When the sensor brings its own data, an entire error source is eliminated.

Compliance is the second reason. ISO standards, GLP guidelines, industry-specific regulations – all require proof of calibration and traceability. With RFID, the system documents itself.

For consumables, the economic aspect comes into play: Original parts are authenticated, counterfeits detected. This protects not just the business, but also measurement quality.

Application Examples

For water meters, RFID enables contactless reading in passing. The meter reader no longer needs to go into the basement – they read the meter from the street.

For geotechnical sensors, the tag stores installation position and calibration history. Even after years in the ground, you still know which sensor it is and how it was calibrated.

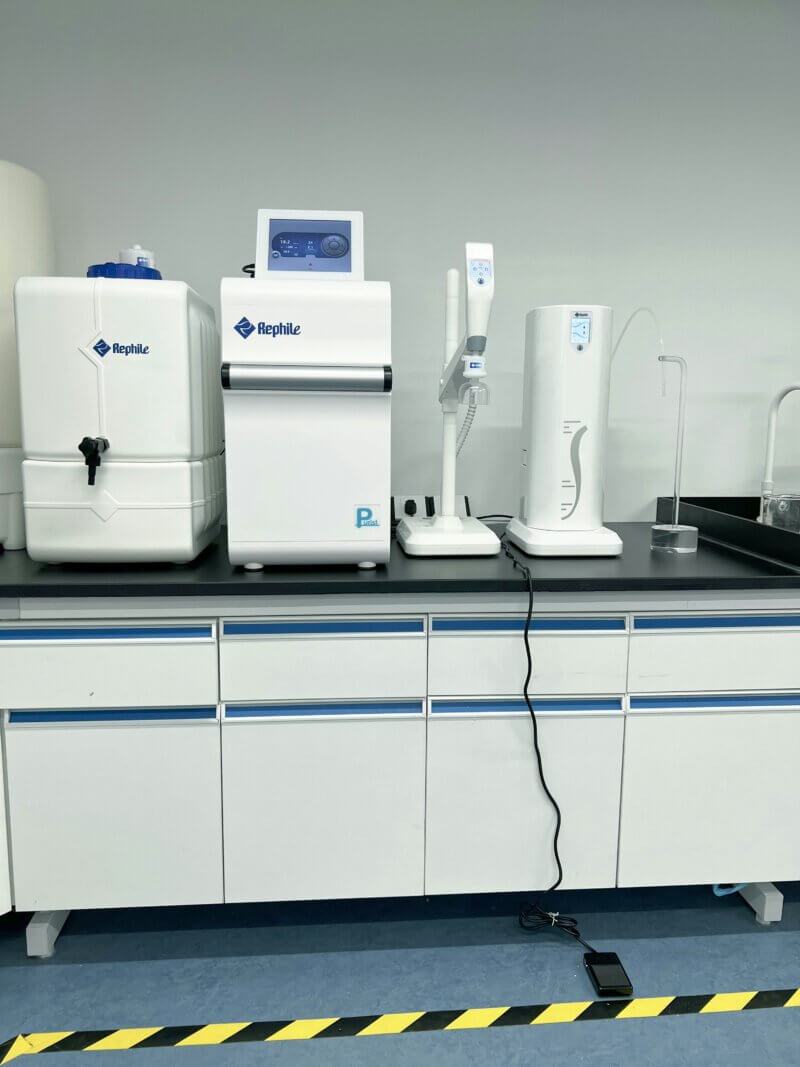

For laboratory instruments, RFID identifies the measurement electrode and automatically loads the matching parameters. Plug-and-play instead of searching through manuals.

What We Deliver

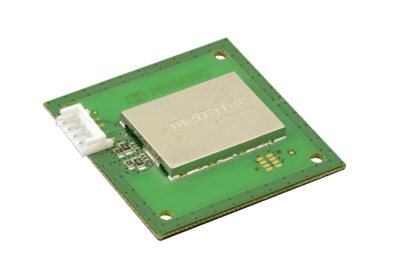

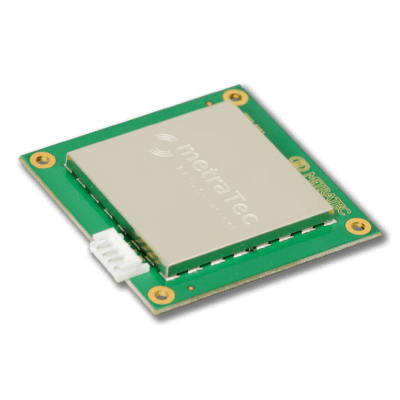

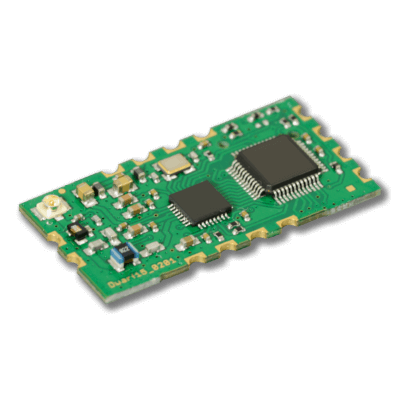

For handheld devices, we offer miniature modules like the Dwarf15 or RR15. For bigger stationary equipment, the QR15 or QRG2 with more range are optimal. The modules read and write, communicate via standard interfaces, and are designed for long-term availability.

Contact: Developing measuring instruments or sensors? Talk to us about RFID integration.