RFID in Industrial Machinery

A CNC operator inserts the wrong tool. The machine mills with incorrect parameters. The workpiece is scrap, worst case the tool is damaged. Such errors cost money and time – and they can be avoided with RFID.

The Problem

Industrial machines work with tools and consumables: milling heads, grinding wheels, filters, ink cartridges, welding wire. Each part has specific parameters, each part wears differently. The machine needs to know what’s currently installed.

Traditionally, manufacturers solve this through magazine positions, barcodes, or manual entry. It works – as long as the operator pays attention. But people make mistakes, especially under time pressure. And none of these methods help against counterfeit spare parts.

The Solution

An RFID tag on the tool or consumable stores all relevant data. The machine reads automatically: What is it? What parameters apply? How long has it been used? After use, the machine writes the updated usage data back.

For a CNC milling machine, this means: The tool is recognized, offsets are loaded automatically, tool life is tracked. For a 3D printer: The filament is identified, print temperature adjusts automatically, remaining quantity is updated.

For spare parts, this works as counterfeit protection: The machine only accepts parts with an authenticated tag. Cheap copies that may not have the same quality are detected and rejected.

Why Manufacturers Want This

Quality is the first reason. Wrong parameters lead to scrap, worn tools to poor surfaces. When the machine always knows what’s installed and how long it’s been running, such errors become rare.

Aftermarket is the second reason. For many machines, the manufacturer earns more from consumables than from the machine itself. If the machine only accepts original parts, it protects this business from cheap competition.

Differentiation is the third reason. RFID tool recognition is a premium feature. It makes the machine easier to operate and justifies a higher price.

The Technical Challenge

Industrial machines mean metal environments, oil, chips, vibrations. Not the environment where RFID typically shines. But it works – with the right components and the right design.

HF technology at 13.56 MHz works even in close proximity to metal, as long as the antenna is positioned correctly. The read range is short – a few centimeters – but that’s enough for tool holders and cartridges.

What We Deliver

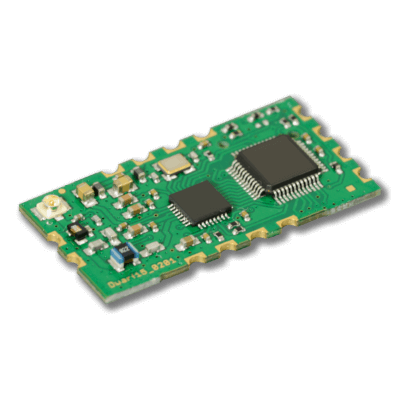

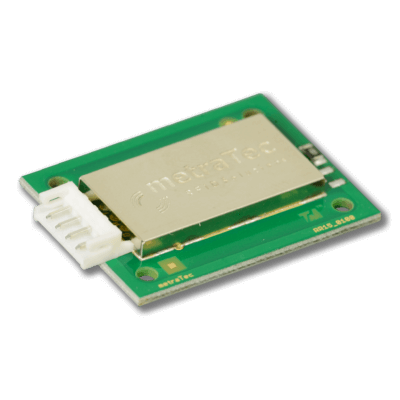

Our compact modules like QR15, Dwarf15, or RR15 are built for exactly these environments: Industrial-grade, with extended temperature range, robust against EMC interference from drives and motors.

We support antenna design – because the right antenna in the right place is crucial. And we guarantee long-term availability, because machines live longer than consumer electronics.

Building industrial machines and considering RFID tool recognition? Talk to our engineering team.