RFID in Laboratory Equipment

An analyzer that accepts the wrong reagent delivers wrong results. In a clinical lab, that can distort diagnoses. In a pharmaceutical company, it can ruin an entire batch. That’s why laboratory equipment manufacturers are increasingly adopting RFID.

The Problem

Laboratory instruments depend on specific reagents and consumables. A plate reader needs matching assay kits, an analyzer needs the right buffers and calibrators. Every batch has different characteristics, every product has an expiration date.

Currently, lab technicians type lot numbers manually or scan barcodes. It works – most of the time. But it costs time, causes errors, and barely keeps up with increasing documentation requirements. For FDA-regulated labs, the burden of proof becomes an administrative nightmare.

The Solution

RFID modules in the instrument recognize reagents automatically. As soon as a reagent container is inserted, the device reads all relevant data: product type, lot number, expiration date, specific calibration parameters. No entry, no scanning, no mix-ups.

The device can also write back: How much reagent was consumed? When was the container opened? This enables true first-in-first-out and prevents forgotten opened reagents.

RFID works for user authentication too: The technician holds their badge to the device, and the system automatically documents who performed which analysis. FDA 21 CFR Part 11 requires exactly that – electronic signatures without password entry.

Why Manufacturers Want This

Quality assurance is the main reason. Wrong reagents mean wrong results, and wrong results mean recalls, liability issues, reputation damage. RFID eliminates an entire class of errors.

The second reason is economic: Reagents are the business model of many laboratory equipment manufacturers. The instrument is sold at slim margins, profit comes from consumables. If the device only accepts original reagents, it protects this business model.

What We Deliver

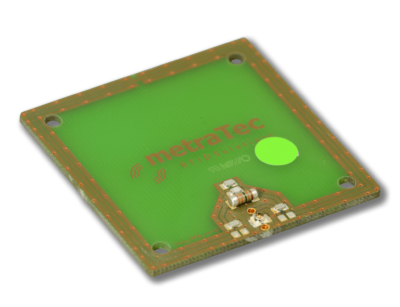

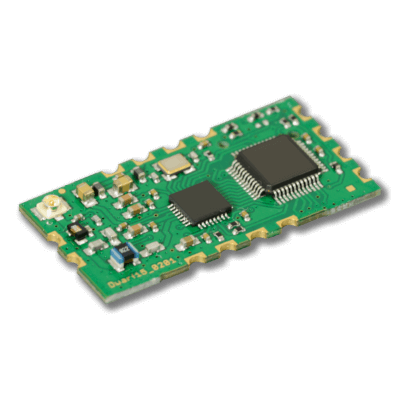

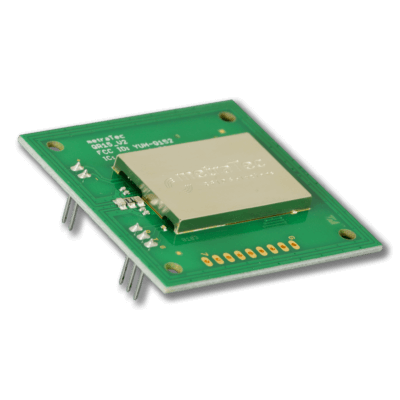

Our HF modules like the QR15 are built for exactly this application: compact enough for benchtop instruments, fast enough for everyday lab work, reliable enough for regulated environments. They read single tags or entire racks with multiple samples simultaneously.

Integration is straightforward – standard interfaces, documented protocols, and an engineering team that helps with antenna design.

Developing laboratory instruments and considering RFID? We’re happy to advise on technical implementation.